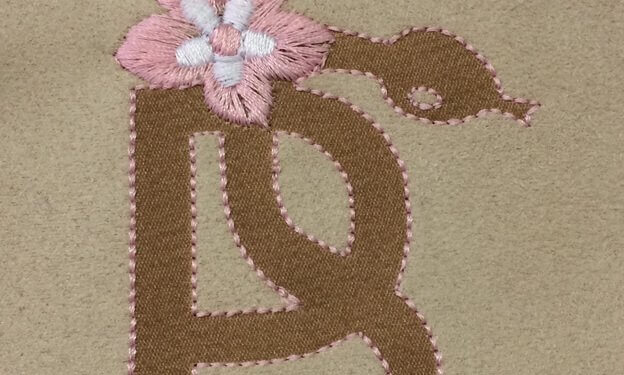

How to awaken customer desires with innovative embroidery artworks.

In last decades garment decoration has experienced the combination and contamination of different techniques: laser cutting, marking, appliqué, rhinestones and so on.

GMI has designed a system for sewing and embroidering patches, badges, labels, appliqué with ease and precision or positioning embroideries on prints with precision, without the need to create trace stitches or use other references.

The system, GMI CamStitch, is composed of a camera which is installed on any single-head embroidery machine.

It is extremely simple to use:

- the camera takes a photo of the item, for example a printed t-shirt.

- the software combines embroidery with printing, without the need of external references and avoiding the error due to positioning done “by hand”.

- In this way it is possible to enrich the print with embroidered details and to create workings never thought of before.

In the case of appliqué, badges, HD or printed labels, the system automatically creates the running stitches or the column stitches on the edge and position them in the correct place.

It is equally interesting the possibility of creating larger embroidery designs than the hoop, as multiple parts of the embroidery design can be precisely matched with the help of the camera.

Finally,it is possible to correct failed embroideries, by adding, for example, embroidery stitches, sequins or missing beads.

In conclusion, thanks to the GMI CamStitch system, embroiderers can surprise their customers with complex and innovative designs.

Discover with GMI staff the competitive advantages of GMI CamStitch, contact us now.