One of the most important advantages of the “laser bridge” cutting system installed on embroidery machines is that the laser works in register with the embroidery machine. That is, the design will reproduced exactly as it was created.

This means that it is not necessary to:

- create stitches that act as reference for laying the appliqué

- cover the edges of the application with N-stitches to “hide” the inaccuracy of the hand-made cut and the reference stitches.

In the jargon of Italian embroiderers, the fact of leaving the edges of the appliqué visible, ie not covered by another thread, saw the birth of the term “clean cut”.

Clean laser cut embroidery appliqué give more competitive advantages:

- save cover embroidery stitches , the time of the designer to create them and the working time of the embroidery machine

- create highly profitable designs, because applications with clean cut edges, with articulated shapes or composed of many small pieces, are carried out at an industrial level only with a laser bridge system

Using other techniques such as cutting the appliqués out of the embroidery machine and following sewing in the machine, the above benefits are not achieved.

How to get quality embroidery appliqué

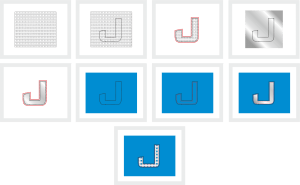

However, appliqué with clean cut edges have a downside: for best results, the embroidery stitches that fix the appliqué must be equidistant from the cut edge. This is achieved both by carefully taking care of the creation of the embroidery + laser file, and by choosing quality machinery. In addition, the machines and the laser bridge must be constantly in register.

For this purpose, GMI has developed two systems to ensure optimal results:

- LS1 automatic calibration systems, to be installed on embroidery machines

- the Vision system for GMI Moda Laserbridge laser bridges. See this video.

- Stilista 3 laser driver PLUS software that control the laser machine. With this software the operatore can move single cuts on single heads, to get top precise cuts.

Further, to get optimal results, it is very important to choose the parameters of cut suitable for the type of process and material. To simplify the choice of cutting parameters, we have implemented in the laser control software, Stilista3, the pre-set parameters specific for Kiss-cutting. Start from this, it will be of great help!

In the next gallery you can see works that combine embroidery with “clean” cut appliqué, even with overlapping appliqué.

Which materials?

If you are not bound in the use of specific materials, we recommend investing some of your time to reflect on the type of design you will create and the materials you will use.

Ask your self these questions:

- does the application material let the light through?

- is the application material homogeneous?

If the answer is yes to one or both questions, PROBABLY you will have to interpose a protective material, such as aluminium foil, between the base fabric and the application.

Why is protection needed in some cases? Because the laser beam is made of light which, at a certain concentration, heats the surface with which it comes into contact. If it encounters a homogeneous and resistant material, its energy is exhausted on that material. Otherwise, if it encounters less thick areas or areas with holes, its energy will affectt the underlying material.

Some materials, such as cotton and wool, are not suitable for “clean cutting” because the edges cannot weld, as is the case with fabrics containing synthetic fibers.

Nevertheless, even with materials composed of cotton fibers you can create interesting effects, without covering the edges. We will talk about it in the next article. In order not to lose it, subscribe to our newsletter.